Authors: Samy Mokeddem, Bardhyl Miftari, Victor Dachet, Guillaume Derval, Damien Ernst

Access to the paper: https://hdl.handle.net/2268/327044

Sectors such as steel, cement, aviation, and shipping are among the most challenging to decarbonize, due to their reliance on high-temperature heat, which is difficult to achieve without burning fossil fuels, the need for energy-dense storage that current batteries cannot provide, and inherent CO2 emissions, such as the decomposition of calcium carbonate in cement production. Consequently, these sectors remain heavily dependent on fossil fuels and face significant challenges in reducing their carbon footprint.

In this paper, we introduce the concept of Distributed E-Fuel Hubs (DEFHs) for producing low-carbon fuels locally and minimizing their cost of production.

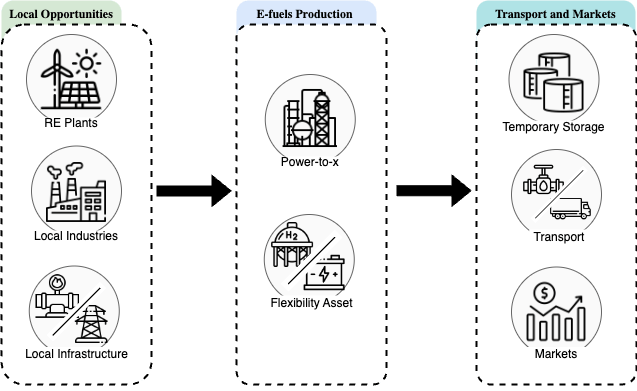

A DEFH is a small, highly integrated production unit designed to:

- Produce electric fuel (e-fuels). E-fuels are energy-dense molecules synthesized using low-carbon electricity such as e-kerosene or e-methane.

- Takes full advantage of local commodities like renewable electricity, CO₂-rich flue gases from nearby factories, and waste heat.

- Valorize valuable synthesis by-products (oxygen, heat) and/or participate in markets like European (EU) Emission Trading System (ETS) and the service-to-grid markets.

- Be close to demand centers like airports, ports, or heavy industry to reduce transport costs.

Instead of one massive centralized plant, DEFHs aims to distribute production across multiple hubs. This distributed production can unlock synergies that centralized production models overlook.

We assess the e-fuel production cost of this concept through a techno-economic analysis involving a DEFH synthesizing Fischer–Tropsch liquids, located near a lime plant in Belgium. Our analysis is based on a Linear Programming (LP) model for system sizing and operation planning, using hourly resolution data over one year. We consider a range of scenarios, from a low integrated DEFH with minimal local commodities integration and no by-products valorization, to a highly integrated scenario where the DEFH takes full advantage of local commodities and valorizes all of its by-products. These various scenarios highlight the impact of integration on e-fuel production cost.

Our results show that DEFH integration can significantly reduce e-fuel production costs, achieving up to a 45% cost reduction in the highly integrated scenario compared to the low-integrated one. This cost reduction is not due to a technological innovation but rather comes from a smarter use of resources.

The DEFH concept is complementary to other CO2 emission reduction strategies, such as increasing low-carbon electricity production or electrifying fossil fuel-intensive sectors. Nevertheless, the DEFH concept represents more than only a technical concept. DEFHs offer a strategic pathway toward a resilient, low-carbon energy future. By taking advantage of existing industrial ecosystems, valorizing unused by-products, and participating in local markets, DEFHs can unlock synergies that centralized production models overlook. Their modularity, adaptability, and potential for rapid deployment make them particularly suited for accelerating the decarbonization of hard-to-abate sectors such as aviation and industry. With appropriate policy support and stakeholder engagement, DEFHs could become a cornerstone of future energy systems – empowering regions to produce clean fuels locally, reduce dependence on imports, and valorize local renewable resources.

Leave a comment