Authors: Antoine Larbanois, Bardhyl Miftari, Antoine Mouchamps, Ayyildiz Kerem Enes, Vincent Schryvers, Guillaume Derval, Damien Ernst

Access to the paper: https://hdl.handle.net/2268/331891

This work is the result of a great collaboration between the University of Liège and the SCK CEN, the Belgian Nuclear Research Centre. In this study, we investigate the integration of a specific type of SMR — a Lead-cooled Fast Reactor (LFR-SMR) with a capacity of 300 MWe (700 MWth) — to supply both heat and electricity to a real industrial site operating off-grid.

💡 Why off-grid?

✅ To avoid the challenges of integrating multiple 300 MWe SMRs into national grids, especially given the uncertainties around grid acceptability.

✅ To improve security of supply — a topic that becomes increasingly important as renewable energy penetration grows and geopolitical tensions affect energy availability.

We evaluated three system configurations, all combining the LFR-SMR with molten salt thermal energy storage and additional conversion/storage units to meet the significant seasonal fluctuations in industrial energy demand:

1️⃣ One with a lithium-ion battery

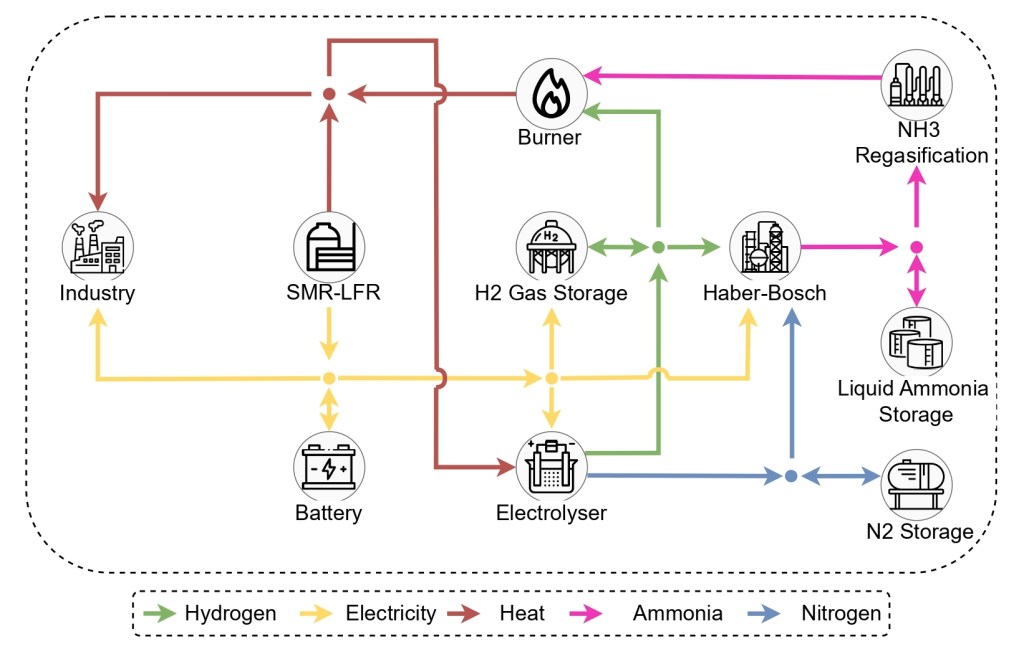

2️⃣ One adding hydrogen production and storage

3️⃣ One combining hydrogen and ammonia as energy carriers, in addition to battery storage

🔍 Each configuration is technically and economically optimized to meet industrial energy needs year-round.

Key results:

✔️ The LFR-SMR can efficiently operate off-grid in all configurations

✔️ E-fuels (hydrogen/ammonia) are more cost-effective than batteries for handling winter peaks

✔️ The LFR-SMR + thermal storage can load-follow most of the year without requiring additional conversion units

📉 Estimated energy costs with e-fuels:

• Heat: €25/MWh

• Electricity: €60/MWh

We note that the additional units needed to guarantee year-round off-grid operation represent less than 5% of the system’s total annual cost.

Leave a comment